Shenzhen Topxel Electronics Technology Company Limited

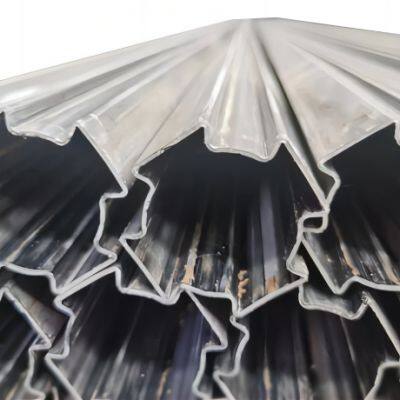

Main Products: CNC machining services, Aluminum machining, brass machining, steel machining, carbon fiber machining

Home > Company Introduction

Company Overview

We started small consumer electronics early in 2005, and engaged in Mobile phone accessories and video products, such as home WIFI IP cameras, car dash cameras, ...and fashion electronic products in 2013. We focused on all kinds of high quality featured electronics which may do special work for our customers. We have a team of technical person with more than 10 years experience. That made us compenent to design and produce special cameras for our customers. Our business mode is " OEM custom" manufacture service, we had ever produced many famous brands of electronic products for our customers.

CNC Machining Services. We started CNC machining and establish our own factory in 2006. In the past 10 years, We focued our sales on our local market (mainly in Shenzhen, Dongguan), Some of our customers are vendors of Huawei, Foxconn. We have a wide variety of mechanical equipments: CNC high speed machining centers, CNC precision automatic lathes, CNC lathes, wire electrical discharge machining (WEDM) and auxiliary processing equipments, 2d and 3D vision measuring machines etc. high-precision testing equipments.Main machining materials are stainless steel, aluminum, titanium, steel, tool steels, brass, bronze, beryllium, copper, nickel, plastics(PET, PP, PMMA), extensive line of exotics.

Design and innovation is a power for our prompt growth since our establishment. Our mission is to find and manufacture more new products specially for our customers' marketing, or to do new features and functions of traditional products. And it is also our business advantage.

"The quality is our life". The quality is as the base of our company's survival and growth. We attach importance to the foundation and perfection of company system administration. Our factory has established a integrated engineer & QC system, and perform on the quality standard system of ISO9001:2000 in our company, and implement "7S" production administration. We have implemented a series of quality control functions that cover all the steps in manufacturing process. The main steps in this quality control procedure include incoming materials inspection, material characteristics testing, soldering etc.

Constant monitoring on all steps in the manufacturing process and information feedback at all levels allow fast and efficient detection of problems, evaluation and analysis, and corrective measures. We emphasize that each step in the manufacturing process should be undertaken with a "Do it right at the first time" attitude and must produce a defect-free output. The overall result is high quality reliable products.

Our production strategic objectives to be achieved is the key that Lean Production Management system steady operation and pay attention to the development of staff and training. In the production practice to make full use of the companys resources, actively implement the" Zero Waste" production management and continuous improvement 7S, put the high-quality and low-cost products to the optimal JIT (time needed, required locations, the number needed ) way to provide global customers in various regions.

Our success is the process that is an ever meet, continue to exceed customer expectations. In order to ensure the achievement of high quality and low cost, R & D engineers and technical staff were starting from a variety of details at the start, to explore and meet the diverse needs of customers, through the processing way of revolutionary practice made pioneering achievement, that allows customers to accumulate the beyond expectation value.

-

Manufacturer, Trading Company, AgentBusiness Type

-

2013Year Established

-

1,000-3,000 square metersFactory Size

-

11 - 50 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

11 - 50 People Total Employees

-

Domestic Market, North America, Western Europe, Northern Europe, Mid East, South America, Eastern Asia, Africa, Oceania, Southern Europe, South Asia, Eastern Europe, Central America Main Markets

-

Shenzhen, Hongkong, Guangzhou Port of Shipment

-

CNC Machine Tools Main Industry